7 Boat Maintenance Tips for Preventing Corrosion in Saltwater

When boats are utilized and kept in saltwater, they are persistently exposed to various corrosive elements. All metallic constituents of the boat, including the tiniest screw or hose clamp, can be impacted by corrosion. In certain cases, the damage caused by corrosion is merely cosmetic, such as pockmarked railing or rusty streaks where finish screws come into contact with gelcoat. Nonetheless, corrosion can also result in bigger issues, such as electrical malfunctions, mechanical failures, and engine problems that can ruin a day of boating and rack up repair bills.

Although corrosion is a persistent adversary, boaters who are proactive with basic maintenance can keep their vessels in top shape, both in appearance and performance. Here are seven maintenance tips for fighting corrosion on your saltwater boat.

1: KEEP IT CLEAN

After every boat trip, it’s essential to thoroughly wash surfaces with soap and freshwater. Simply hosing down the deck will not suffice; instead, wash and scrub the entire vessel from front to back, with special attention given to metal components such as railings, hinges, and rod holders. We recommended using a rag or soft-bristled brush on all areas except the cockpit sole.

Flush the boat's engine for at least five minutes with freshwater to eliminate any saltwater remnants from the cooling system. This step should never be skipped, no matter how rushed you are.

If you keep your boat on a trailer, wash the trailer with soap and water, ensuring that all salt is rinsed off the brakes. Most trailers with brakes have brake flush ports that enable you to connect a freshwater hose and flush for several minutes. Even if your trailer does not have this feature, use the washdown hose to clean the wheels and brakes from the exterior.

2: KEEP IT PROTECTED

If your boat is stored in a slip, ensure that the outboard engine or I/O lower unit is tilted to the highest position to avoid constant exposure to saltwater. It’s crucial to always cover your boat when not in use, whether in a slip or on a trailer. After washing, dry the boat with a towel and install a full cover after each trip. Consider investing in custom-made covers since they fit your boat perfectly and help prevent rainwater or condensation from accumulating.

3: MIND YOUR ZINCS

It’s essential to be aware of the location of all sacrificial zinc anodes on your boat and replace them if they are corroded. These zinc tabs are typically situated on the engine lower unit and transom, but they can also be found inside the engine compartment, part of your running gear, and elsewhere. Refer to your boat and engine owner's manual to confirm the number and location of these anodes. Zincs are designed to erode gradually - as they do, they sacrifice themselves to shield other metallic components from galvanic corrosion. If they are ignored and deteriorate, they cannot provide this protective function.

4: LUBRICATE ALL THE LITTLE THINGS

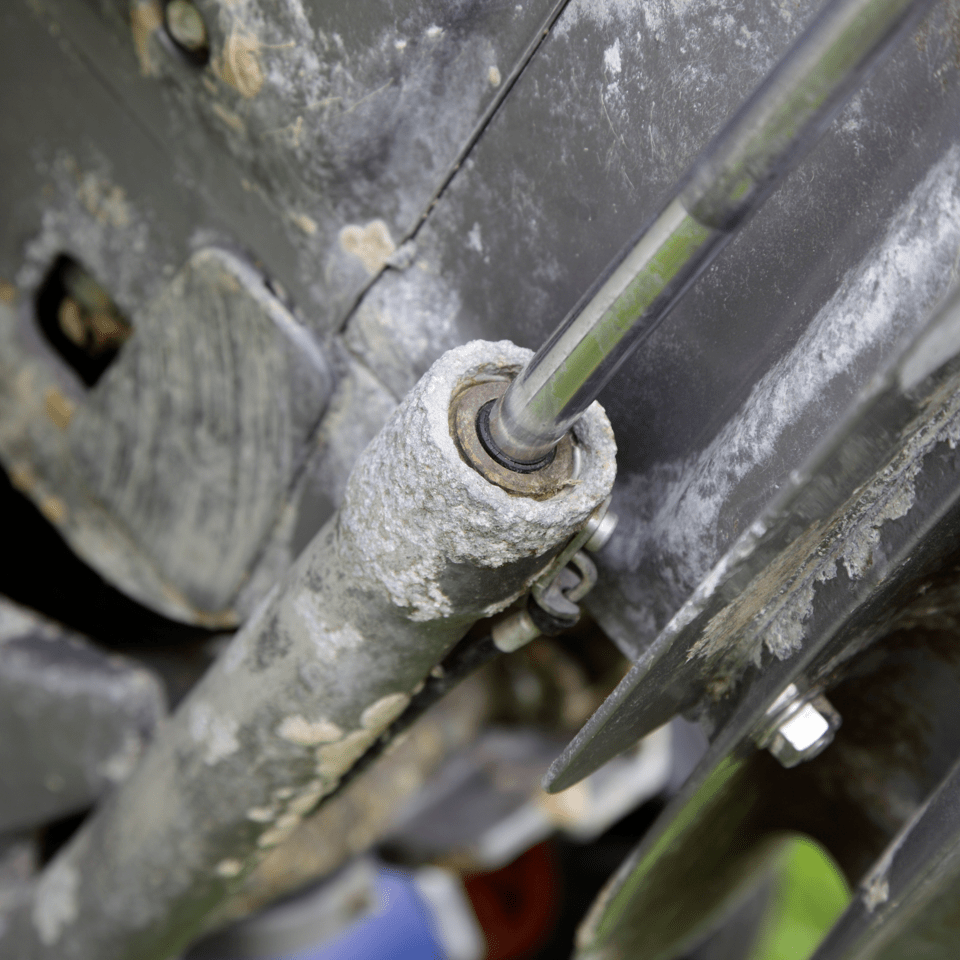

Lubrication not only ensures smooth movement but also provides protection against rust and water intrusion. Apply marine grease to the fittings on your outboard steering tilt tube and engine trim mechanism. For sterndrive boats, lubricate the gimbal bearing and engine coupler.

Apply a light coat of moisture-displacing lubricant to all the moving metal parts on your boat such as latches, hinges, linkages, bow rollers, trailer winch rollers, and other components. Remember, if it's metal and moves, it needs lubrication. Refer to your boat and engine owner's manual to ensure that you have identified all recommended lubrication points.

Don’t forget to check the grease fittings on your trailer’s wheel bearings and top them off if needed. Periodically remove and inspect wheel bearings for signs of corrosion, pitting and excessive wear. Replace and/or re-pack trailer wheel bearings to prevent corrosion, possible roadside breakdowns and severe damage to your trailer or boat.

5: PROTECT YOUR ENGINE & FUEL SYSTEM

Even with meticulous care of visible corrosion, the most destructive type can occur in concealed areas such as inside the boat’s fuel system and engine. To protect against such corrosion on boats used in saltwater, use a top-quality marine fuel additive that stabilizes the fuel during storage. Ensure the boat is stored with a full tank of fuel (95% or more) and inspect the fuel lines, fittings, hose clamps, inline fuel filters, and water-separating fuel filters. Clean or replace any parts that appear dirty or damaged to prevent engine and fuel system damage.

6: CHECK YOUR POWER SYSTEMS

Battery terminals and connections are prone to corrosion, which can cause ignition or power supply issues while out on the water. To prevent this, incorporate a visual inspection of your battery posts and connecting terminals into your regular maintenance routine. Ensure that all of your boat's batteries are checked, including starting, house, and trolling motor batteries. If necessary, remove the terminals, use a wire brush to clean both the posts and terminals, and reattach them tightly. Applying battery terminal spray or white dielectric grease to the connections can prevent future corrosion. Additionally, inspect battery cables for any signs of damage, such as cuts or nicks in the insulation. These can allow corrosion to spread and damage the cables. Any damaged battery power cables should be replaced.

7: LOOK BENEATH THE SURFACE

Corrosion can sneak up in unexpected places on your boat. Don't forget to check under open hatches and storage lockers, and peek behind your steering helm. Take a close look at your marine electronics connections, bus bars, and wiring bundles. Check all your boat's thru-hull pickups, seacocks, plumbing systems, and hose clamps. Replace anything that appears even slightly questionable before it becomes a bigger issue. If you see rust streaks emanating from screws, saltwater may be infiltrating behind them. Remove and replace them with new stainless-steel screws, and seal them with marine bedding compound.

RUST NEVER SLEEPS…

Neil Young once sang, "Rust never sleeps," and this is especially true for boats that spend their days in salt water. The good news is that boaters who make it a priority to combat corrosion as part of their year-round maintenance routine can keep rust from spoiling a perfect day on the water.

Leave a comment